Cutting rebar is an essential skill for anyone involved in construction projects. Whether you’re a professional contractor or a DIY enthusiast, knowing how to properly cut these reinforcement steel bars is crucial for ensuring the structural integrity and safety of your work. In this ultimate guide, we’ll walk you through everything you need to know about cutting rebar, from understanding the different types and sizes to selecting the right tools and following essential safety measures. By the end of this article, you’ll be equipped with the knowledge and confidence to tackle any rebar cutting task efficiently and safely.

Learn how to cut rebar safely and efficiently with this comprehensive guide. Discover the best tools, techniques, and safety measures for cutting reinforcement steel bars in your construction projects.

Table of Contents

ToggleUnderstanding Rebar

Before diving into the cutting process, it’s essential to understand what rebar is and why it’s used in construction. Rebar, short for reinforcement steel bar, is a steel bar or mesh used to strengthen concrete and masonry structures. Its primary purpose is to provide tensile strength, helping to resist cracking and splitting under stress.

Rebar comes in various sizes, typically designated by a number that corresponds to its diameter in eighths of an inch. For example, #4 rebar has a diameter of 4/8″ or 1/2″. The most common sizes used in residential and commercial construction are #3, #4, and #5.

In addition to size, rebar is also classified by grade, which refers to its yield strength. The most common grades are Grade 40 (40,000 psi yield strength) and Grade 60 (60,000 psi yield strength). It’s crucial to use the appropriate size and grade of rebar specified in your project plans to ensure proper reinforcement.

Safety First: Precautions and Equipment

Before beginning any rebar cutting task, safety should always be your top priority. Cutting rebar involves working with sharp, heavy materials and potentially dangerous tools, so it’s essential to take the necessary precautions to protect yourself and others around you.

Start by wearing appropriate personal protective equipment (PPE):

- Safety glasses or goggles to protect your eyes from metal debris and sparks

- Cut-resistant gloves to protect your hands from sharp edges and potential injuries

- Steel-toed boots to protect your feet from falling rebar or heavy objects

- A hard hat to protect your head from falling debris or accidental impacts

- Hearing protection when using power tools

- Next, choose a safe work area. Select a well-ventilated space away from flammable materials, and ensure a stable, level surface for cutting. Keep the area clean and free of trip hazards. When working on renovation projects, always check for hidden utilities like electrical wires, gas lines, or water pipes before cutting. Use a utility detector or consult blueprints to identify potential hazards.

Tools for Cutting Rebar

There are several tools available for cutting rebar, each with its advantages and disadvantages. The choice between manual and power tools will depend on the size of your project, the diameter of the rebar, and personal preference.

Manual tools:

Bolt cutters: Suitable for cutting small-diameter rebar (up to #4) with minimal effort.

Hacksaw: Versatile tool for cutting rebar of various sizes; requires more time and effort

compared to power tools.

Rebar cutter/snips: Specialized manual tool designed for cutting rebar; provides clean cuts with minimal effort

Power tools:

Angle grinder with metal cutting blade: Efficient for cutting rebar of all sizes; requires

proper handling and safety precautions. An angle grinder is often considered the best way to cut rebar due to its speed and versatility.

Reciprocating saw with metal cutting blade: Portable and versatile option for cutting rebar; ideal for tight spaces or in-place cutting.

Portable bandsaw: Powerful tool for cutting large-diameter rebar; offers precise, clean cuts.

When it comes to the easiest way to cut rebar, power tools like angle grinders and reciprocating saws are generally the most efficient options. However, for those on a budget or working on smaller projects, manual tools can still get the job done effectively.

Step-by-Step Guide for Cutting Rebar

Now that you understand the basics of rebar and have your safety gear and tools ready, let’s walk through the step-by-step process of cutting rebar.

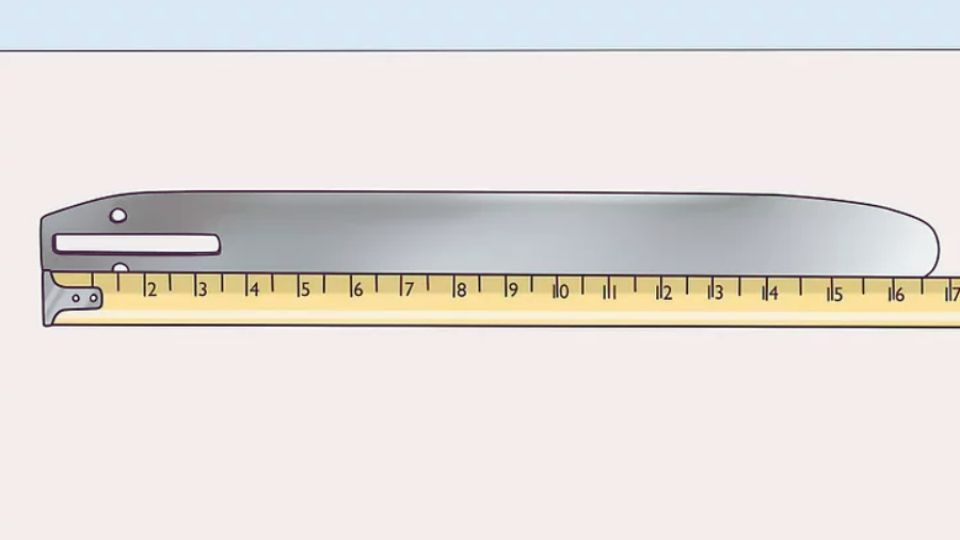

Measure and mark the rebar:

- Use a tape measure or ruler to determine the desired length of the rebar.

- Mark the cutting point with a chalk line or permanent marker, ensuring the mark is visible and accurate.

Secure the rebar:

- Place the rebar on a stable surface, such as a workbench or sawhorse.

- Use clamps or a vice to hold the rebar firmly in place, preventing it from slipping or moving during the cutting process.

Choose the appropriate cutting tool:

- Select the cutting tool based on the size of the rebar, personal preference, and available equipment.

- Ensure the tool is in good condition, sharp, and equipped with the proper blade or cutting edge.

Cut the rebar:

- For manual tools (e.g., bolt cutters, hacksaw):

- Align the cutting tool with the marked cutting point.

- Apply steady pressure and use a consistent back-and-forth motion to cut through the rebar.Maintain a straight blade alignment and keep a firm grip on the tool.

For power tools (e.g., angle grinder, reciprocating saw):

- Ensure the tool is equipped with the appropriate metal cutting blade.

- Align the blade with the marked cutting point.

- Cut through the rebar using firm, controlled motions, allowing the blade to do the work.

- Keep the tool steady and maintain a consistent cutting speed.

Smooth the cut edges (optional):

- If desired, use a metal file or grinder to smooth any rough edges or burrs on the cut end of the rebar.

- This step is important if the rebar will be handled frequently or if a clean appearance is required.

Clean up:

- Dispose of any metal debris or dust properly, as it can be sharp and hazardous.

- Clean and store tools according to the manufacturer’s guidelines to maintain their longevity and performance.

- Sweep or vacuum the work area to remove any metal shavings or debris.

Maintenance, Storage, and Disposal

To ensure the longevity and performance of your cutting tools, proper maintenance and storage are essential. Regularly clean and lubricate manual tools to prevent rust and ensure smooth operation. Follow the manufacturer’s instructions for cleaning and maintaining power tools, including blade replacements and lubrication.

Store rebar in a dry, covered area to prevent rust and deterioration. Keep cutting tools in a secure, dry location, protected from moisture and damage. Regularly inspect cutting tools for signs of wear, damage, or dullness, and replace as needed. Check rebar for excessive rust, bends, or other defects before cutting and using in projects.

Proper disposal of cut rebar pieces is crucial for safety and environmental reasons. Collect the cut pieces and store them in a designated scrap metal bin or container. Transport the rebar to a scrap metal recycling facility for proper processing and recycling. Always follow local regulations and guidelines for disposing of metal waste.

Can You Cut Rebar with a Hacksaw?

One common question that arises when discussing rebar cutting is, Can you cut rebar with a hacksaw? The answer is yes, you can indeed cut rebar using a hacksaw. While it may require more time and effort compared to power tools, a hacksaw is a viable option for cutting rebar, especially for smaller diameters or when power tools are not available.

Why did I need a Sawzall?

Although I work with contractors who have specialized tools and they can provide me with all my power tools, there are times when I must take matters into my own hands. Lately, that often includes cutting Reber.

For example, we’re putting in new posts for an addition at a property I manage and those posts are made of steel beams. The only way to get them down where they belong is by cutting them first and it has become apparent that our contractor isn’t going to do it because he doesn’t have a Sawzall (the tool used to make these cuts).

That means no post holes for another week because I need another one of these. So what do you do? You go out and buy yourself a Sawzall.

But how do you use it? How much does it cost? What kind should I buy? These are all questions I had as well so let’s talk about how to cut rebar with a Sawzall.

How to cut rebar like a pro with a Sawzall (step by step)

Using a Sawzall to cut rebar is easy if you have the know-how and are prepared. Here’s an example of what I’ve done in my DIY home improvement projects.

Step 1: Pick a sharp blade:

First, you need to pick out a good blade for your Sawzall. I’ve found that using an industrial-grade metal cutting blade works best. This is because it’s designed for cutting through steel and will last longer than standard construction blades.

It’s also worth noting that you should never use anything other than a metal cutting blade when cutting rebar. If you try to use anything else, you risk dulling your blade quickly and even damaging your Sawzall or other tools in your toolbox.

Step 2: Measure out the length of the bar:

You’ll want to measure out how long of a piece of rebar you’re going to be able to cut off at one time so that it fits into your toolbox without being too heavy or awkward for you to lift and carry around.

I’ve found that cutting pieces about 4 feet in length works best for me, but it’s important to remember that every job is different and you should adjust accordingly.

For example, if you’re working on something small and lightweight like a deck railing, then you might only need to cut 10-inch pieces. If you are building something larger like structural support beams for addition to your home or business, then 6-foot sections will probably work better.

Also, keep in mind that larger sections will require more weight than smaller ones. So plan and make sure that whatever size piece of rebar you decide on can easily fit into your toolbox before proceeding to step 3 below.

Step 3: Make sure Sawzall is set up for metal cutting blade:

Before you can use your Sawzall, you’ll need to make sure that it’s set up properly. First, make sure that your Sawzall is in reverse and locked into place. This will ensure that you don’t accidentally try to cut wood or plastic instead of steel.

Then, check your toolbox and make sure that your metal cutting blade is securely attached and ready for use. If not, then remove any other blades first and replace them with your metal cutting blade before proceeding to step 4 below.

Step 4: Position Sawzall so that it’s perpendicular to the bar:

You’ll want to position your Sawzall so that it’s perpendicular to your piece of rebar. This will ensure that you get a clean, straight cut and avoid damaging your blade or toolbox.

You’ll want to position your Sawzall so that it’s perpendicular to your piece of rebar. This will ensure that you get a clean, straight cut and avoid damaging your blade or toolbox.

It also helps make sure that you don’t accidentally start cutting at an angle and risk nicking your blade in half. If you’re working on something small, then I recommend holding your Sawzall in one hand and using your other hand as support for added stability.

If you’re working on something larger, then I recommend setting up some sort of workstation so that both hands are free while still allowing you plenty of room for movement.

Step 5: Make sure you’re cutting in a straight line:

When you start cutting, you must be able to see where your blade is going. This will help ensure that you don’t accidentally veer off course and risk damaging your Sawzall or other tools in your toolbox.

If you’re working on something small, then I recommend using some sort of guide so that your blade doesn’t go too far past what you’re trying to cut.

For example, if I’m working on something like a deck railing, then I’ll use my hand as a guide by holding it flat against whatever I’m trying to cut.

Step 6: Cut through the bar in one continuous motion:

When you start cutting, you must do so in one continuous motion. This will help ensure that your blade doesn’t get stuck or damaged while trying to go back and forth.

Also, if you’re working on something large and heavy, then I recommend counting out loud as you cut so that you can keep track of how far along you are.

For example, when I’m cutting steel for structural support beams for an addition to my home or business, then I’ll count out loud as I go by saying things like one after every foot or two after every two feet.

This helps me keep track of where I am without having to stop and look at my progress every few seconds. You can also read the cutting guide of Steel Pipe With Sawzall.

What type of blade should I use?

Sawzalls come with a variety of different blade sizes, as do their replacements. It’s important to know which ones will fit on your machine. When working with metal bars such as steel rebar, use either a steel-reinforced concrete cutting blade or one designed for masonry (i.e., mortar).

If you plan on cutting thick steel bars, you may need an extra-large blade capable of moving in and out quickly-smaller blades can get stuck in heavy metal and send sparks flying if not properly lubricated.

Make sure to keep your blade sharp at all times; dull blades are more likely to crack when they hit something hard.

Safety Measures

When cutting rebar you should always wear protective gear. Safety glasses, dust masks, and earplugs are all good items to have on hand. It’s also important that no one else is around while you’re cutting because of flying debris.

You can protect yourself by wearing a long sleeve shirt and pants as well as thick gloves. If you have any cuts or scrapes it’s best to cover them up with bandages so they don’t get infected.

You should also make sure your area is well ventilated so there isn’t too much dust in the air from cutting rebar.

Conclusion

Cutting rebar may seem daunting at first, but with the right knowledge, tools, and safety precautions, it becomes a manageable and essential skill for any construction project. By familiarizing yourself with the different types of rebar, investing in the appropriate cutting tools, and following the step-by-step guide provided in this article, you’ll be able to approach rebar cutting with confidence and precision.

Remember, the key to successful rebar cutting lies in prioritizing safety at every step. By wearing the necessary personal protective equipment, selecting a secure work area, and maintaining your tools properly, you can significantly reduce the risk of accidents and injuries on the job site.

Armed with the information and techniques outlined in this comprehensive guide, you’re now ready to tackle any rebar cutting challenge that comes your way. Whether you’re working on a small DIY project or a large-scale commercial construction site, the skills you’ve learned will prove invaluable in ensuring the structural integrity and safety of your work.

So, embrace the knowledge you’ve gained, put safety first, and approach your next rebar cutting task with the expertise and confidence of a true professional. Happy cutting!